ENGINE BLOCK COMPONENTS

【CAPACITY UPGRADE KIT

RB26 2.8L STEP3 H-COMP Φ86.5】

High strength “RB28 STEP3 KIT”, designed for use with high power of 1,000 hp or more, is now available in a high-compression version using “Φ86.5 bore size pistons”. Achieved higher output through higher compression, and increased cylinder wall thickness to achieve corresponding output increase.

Specification

| 2.8L D86.5 | 2.8L D87 | Nissan Genuine | |

|---|---|---|---|

| Bore | 86.5mm | 87.0mm | 86.0mm |

| Stroke | 77.7mm | 77.7mm | 73.7mm |

| Comp. ratio (t=1.2) | 9.0 | 8.7 | - |

| Allowable RPM | 9,000rpm | 9,000rpm | 7,600rpm |

| Displacement | 2,740cc | 2,771cc | 2,568cc |

Features

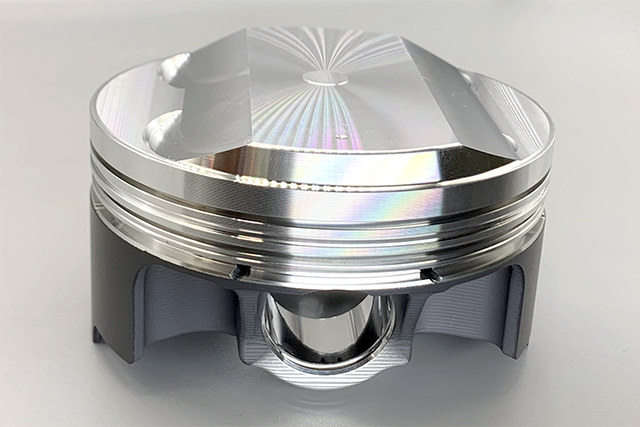

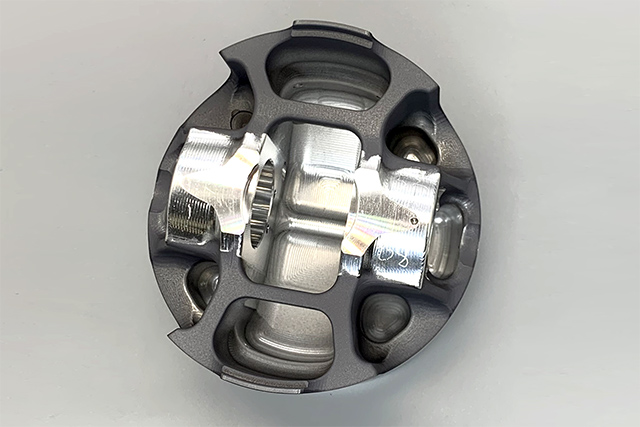

High strength “RB28 STEP3 KIT”, designed for use with high power of 1,000 hp or more, is now available in a high-compression version using “Φ86.5 bore size pistons”. Achieved higher output through higher compression, and increased cylinder wall thickness to achieve corresponding output increase.

(1) Piston Weight: 320g

- The D86.5mm bore size allows the block to be used with minimum boring process until the next overhaul, and a separately available D87mm kit can be used when overhaul is required. Increased cylinder wall thickness to achieve corresponding output increase.

- Higher compression allows the use of higher octane fuel for more power.

- The use of high-temperature-strength A2618 alloy allows to design thinner wall construction.

- Machining from billet eliminates unnecessary weight.

- The BCD (Bridge Concept Design) structure enhances structural rigidity.

- A dual-layer molybdenum coating improves initial wear-in characteristics and reduces friction.

- Shortened D22mm piston pin is used to achieve both increased bending stiffness and reduced weight.

Highly rigid, lightweight piston machined from high-temperature strength A2618 alloy

(2) Crankshaft Stroke: 77.7mm

- A fully counterweighted, billet-machined crankshaft has been adopted. In order to reduce the load on the main bearing under high power, the counterweight has been effectively increased to achieve a higher weight balance.

- In order to accommodate the required maximum output, the material was changed to the nitriding steel and the ion nitriding treatment was applied to increase surface hardness and thicken the hardened layer for improved durability.

The best materials and the best heat treatment are combined to produce a strong crankshaft

(3) Connecting rod

- Billet H-beam connecting rods made from nickel-chromium steel

- Designed to accommodate D22mm piston pins.

- To improve fatigue strength, the surface has been treated with WPC (Wide Peening and Cleaning) processing.

Special lightweight pin enlarged to D22mm to handle high combustion pressure