ENGINE BLOCK COMPONENTS

【Capacity Upgrade Kit VR38DETT 4.3L STEP Pro BCD】

The strengthened crankshaft can withstand even higher torque based on the VR38 4.3L STEP3 KIT

Features

- The crank for STEP Pro changed the material to nitride steel and treated the surface with ion nitriding to improve durability by enhancing the surface hardness and hardened layer.

- Expand the R-corner of the fillet weld in the crankpin to improve the torsion strength.

- Prevents fretting by extending the crank nose 10 mm longer.

- The counterweight employs an asymmetric shape to be compatible with the torsion strength and the response.

- The tungsten is used on the counterweight to achieve the balance rate improvement and response.

-

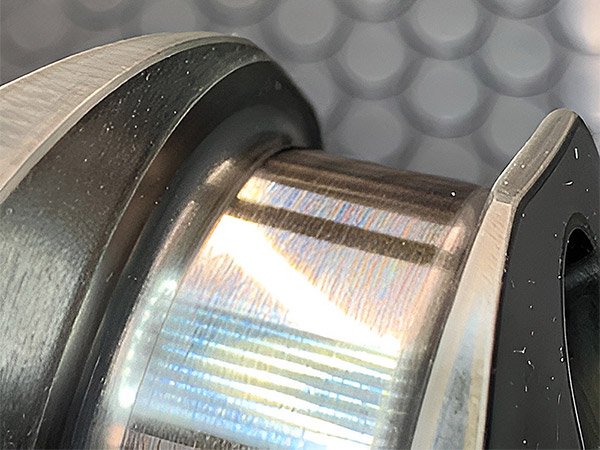

Pulley mounting part that extended 10 mm and highly efficient counterweight using the tungsten.

-

Expand the R-corner of the fillet weld in the crankpin to improve the torsional rigidity of the crankshaft

-

The connecting rod with a clearance shape to avoid contact with the enlarged R-corner of the fillet weld in the crankpin.

-

An asymmetrical crank having an increased thickness counterweight #8 for increased torsional strength.

-

Reduced weight for counterweights #2 and #5 to improve response.

-

The billet piston uses A2618 material with high-temperature strength.

Specifications

| HKS 4.3L KIT | Stock | |

|---|---|---|

| Bore | 95.5mm | 95.5mm |

| Stroke | 99.0mm | 88.4mm |

| Compression Ratio (t=0.8) |

8.6 | 9.0 |

| Allowable Rotation Speed |

7,400rpm | 7,000rpm |

| Displacement | 4,255ml | 3,799ml |

【CONROD BEARING ADJUSTMENT VR43 STEP Pro】

Introducing a clearance adjustment and chamfering service for the connecting rod bearings of the VR38 4.3L STEP Pro.

Features

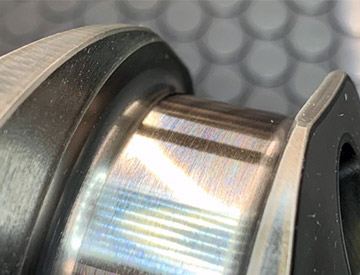

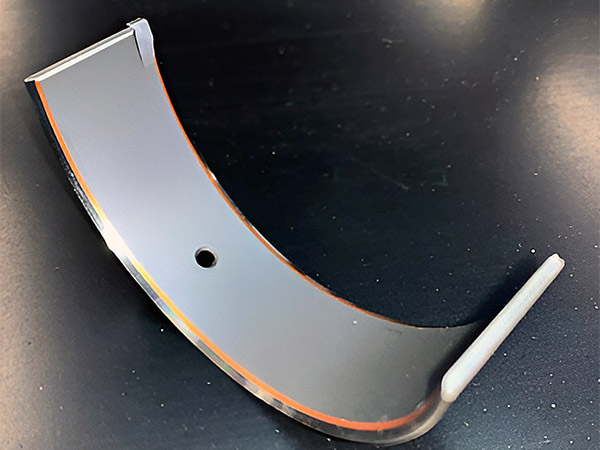

- The crankshaft for the VR43 STEP Pro has an enlarged corner radius at the crank pin to increase torsional strength. This requires chamfering of the connecting rod bearings.

- When you purchase a new STEP Pro FULL KIT, we will provide a service to adjust the clearance of the sub-metal and chamfer the bearings for an additional fee.

- The connecting rod bearings are genuine Nissan parts that are also used in our COMPLETE ENGINE and have been WPC treated.

- Once the adjustment is complete, the product will be temporarily assembled with a connecting rod and delivered. The connecting rods will be stamped with numbers 1 to 6 to identify the cylinders.

- Please note that the bearing surface will be slightly scratched by the cylinder gauge probe, but this will not affect the function.

-

The corner R of the pin part has been enlarged.

-

The big end of the connecting rod is chamfered.

-

Pre-installed connecting rod bearings