HKS COMPLETE ENGINES

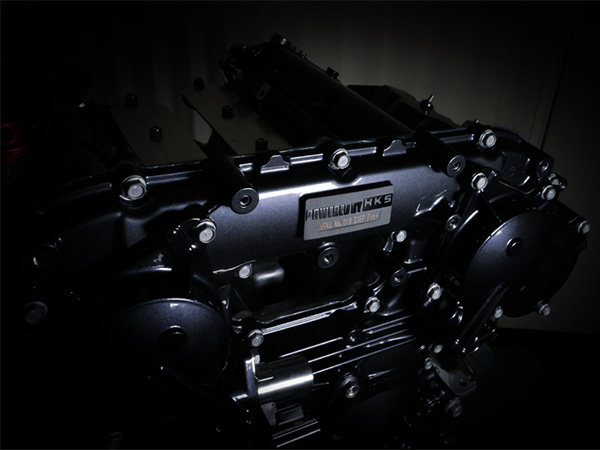

【COMPLETE ENGINE for VR38DETT 4.3L STEP Pro+】

Top-of-the-line STEP Pro+ added to COMPLETE ENGINE VR4.3L

・Focused Driving Situations: Circuit, Time Attack, Drag Racing, etc.

・Maximum Torque: ~1900N・m

* Maximum torque is a value calculated based on our in-house test data, we do not ensure that the product can be used without failure.

*Please note that the figure of torque is fluctuated depends on the condition such as vehicle spec, track condition, driving situation or the distance of driving.

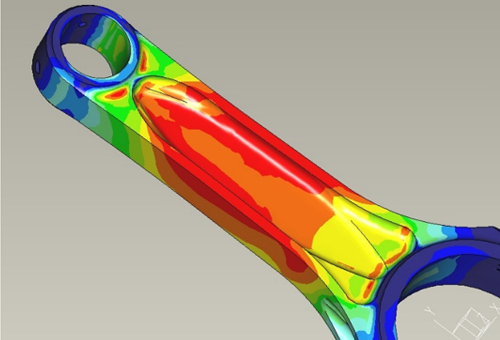

For the COMPLETE ENGINE VR4.3 STEP Pro + that is capable for even higher torque, a special I-beam con rod was developed that has a higher buckling strength than the H-beam con rod. In addition, specially designed crankshaft to further increase torsional rigidity. The area of the dangerous cross-section is enlarged by larger pin diameter, and the asymmetrical design of the critical section between pins #5 and #6, where the stress is highest, is thickened only. This minimizes the increase in weight and optimizes the balance ratio by reviewing the counterweight to match the increased weight of the pin section.

Features

STEP Pro+

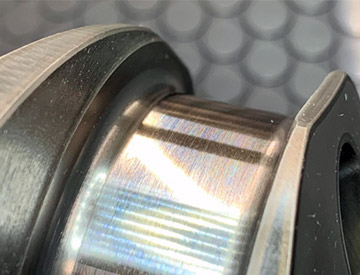

- In addition to STEP Pro crank made of high-end racing grade nitriding steel, STEP Pro+ crank is treated with ion plasma to increase surface strength and toughness required of high cycle performance crankshaft.

- Enlarged crankpin to D57, and inside corner radius to 3.5 for improved torsional strength.

- New billet I-beam connecting rod for SETP Pro + made from a single piece of flat forged steel has 26% higher buckling strength.

- 10mm extension in the front of crankshaft to prevent crank pulley fretting

- Double layer coated piston is specially designed for Pro + effective for sliding under high loads and rotation.

- Special 3D-Printed oil jet to fit the I-Beam connecting rod.

HKS Complete engine series

- HKS original oversize main stud bolts

- #2 and #3 main journal made of Chrome Molybdenum for improved durability

- Line boring to ensure the roundness of main journal.

- Main and connecting rod bearings were selected after numerous rigorous tests

- High thermal conductivity beryllium-free copper valve seats and phosphor bronze valve guides

- HKS metal head gaskets and extra-strong head studs for improved sealing

- HKS high lift camshafts for improved performance in high rpm

Note: HKS recommends using HKS Racing Pro 10W50 engine oil.

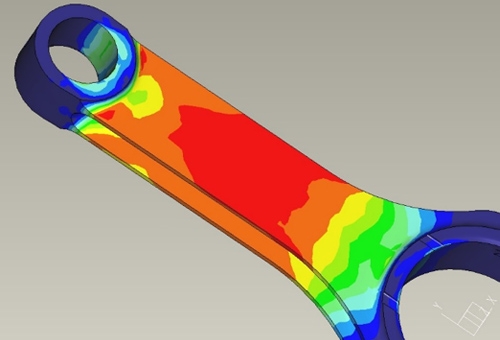

Connecting Rods

New billet I-Beam connecting rods for STEP Pro + improved buckling strength by 26%.

H-beam connecting rod is lightweight, tensile and buckling strength are excellently balanced. However, looking only at buckling strength, the side walls where stress is high are thinner which could be a fracture origin at high torque. (red part)

Thick side I-beam connecting rod for STEP Pro+ was developed to improve buckling strength significantly. Stress will not concentrate on one area benefit from the new lightweight design. (red part)

Big end is also developed to distribute the surface pressure of connecting rod bearing.

| STEP3 / STEP Pro |

STEP Pro+ | |

|---|---|---|

| Weidht | 720g | 752g |

| Torque Capavility |

150kgf.m (approx.) |

190kgf.m (approx.) |

STEP3/STEP Pro

H-Beam Connecting Rod

STEP Pro+

I-Beam Connecting Rod

STEP Pro+

I-Beam Connecting Rod

Special 3D-Printed oil jet to fit the I-Beam connecting rod

Pistons

STEP Pro+ double-layer coated lightweight billet piston made from highly heat resistant A2618 alloy.

(only for STPE pro +)Port and Polish Heads

Combustion chamber and in/ex ports have been mirror finished by HKS's one of the most experienced engine builders.

Connecting Rod Bearing

Bearing for billet I-beam connecting rod

(D57, only for STEP Pro+)Crankshaft

Crank pin diameter and inside corner radius are enlarged to increase torsional rigidity.

(only for STEP Pro+)Main Journal

Extra-strong bearing caps for #2 and #3 made of Chrome Molybdenum, and line boring for improved accuracy (STEP Pro & STEP Pro+)

Crank Pulley

Original VR43 crank damper

(co-developed with ATI)Exclusive Emblem

DLC coating emblem exclusively for Pro+

Original Crankshaft

Asymmetric crankshaft designed to increase strength and decrease inertial weight at the same time

Specifications

| HKS 4.3L KIT | STOCK | |

|---|---|---|

| Bore | 95.5mm | 95.5mm |

| Stroke | 99.0mm | 88.4mm |

| Comp. ratio (t=0.8) | 8.6 | 9.0 |

| Allowable RPM | 7,400rpm | 7,000rpm |

| Displacement | 4,255cc | 3,799cc |

COMPLETE ENGINE VR38DETT 4.3L STEP Pro+

| Engine Head Modifications | Seat: Beryllium-Free Copper / Guide: Phosphor Bronze |

| Step removal and polishing around the sheet | |

| Combustion chamber polishing finish | |

| Camshaft | HKS IN:270° / LIFT 11mm |

| HKS EX:278° / LIFT 11mm | |

| Valve Spring | HKS Strengthened |

| Valve | Adjusted to seat |

| Head Gasket | HKS Metal Gasket (t=0.8) |

| Head Bolt | ARP Strengthened Stud Bolt |

| Block Modifications | #2 and #3 Chrome Molybdenum Cap |

| Oversize Main bearing thread | |

| Enlarged ladder cap hole | |

| Journal oil hole line boring | |

| Honing | |

| Main Bolt | HKS M12 Stud Bolt (625+) |

| Piston | HKS billet (Double-layered molybdenum coating) |

| Connecting Rod | STEP Pro+ billet I-Beam |

| Oil Jets | STEP Pro+ 3D-Printed |

| Crankshaft | STEP Pro+ HKS billet (nitride steel & ion plasma heat treatment D57 crankpin enlarged) |

| Main Bearing | ACL |

| Connecting Rod Bearing | ACL (width adjusted) |

| Crank Pulley | Original VR43 Damper |

| Cover | Baking finish |

| Spark Plug | HKS M50HL |