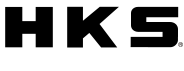

ENGINE BLOCK COMPONENTS

【Short block VR38 4.3L STEP Pro】

A short block that includes the VR38 4.3L Capacity Upgrade kit.

It further strengthened the crankshaft and crankshaft main bearing cap for assuming the circuit driving.

・Expected use scene: Circuit

・Assumed torque: ~ 1500 N∙m

The assumed torque came from the in-house test data. We do not guarantee the use of the product without any damage.

Please note that the allowable torque may vary depending on the specifications of a vehicle, road surface conditions, driving conditions, travel distances, and so on when using the product on the actual vehicle.

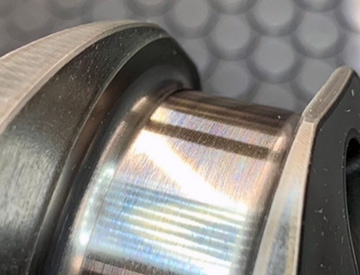

- The crank for STEP Pro changed the material to nitride steel and treated the surface with ion nitriding to improve durability by enhancing the surface hardness and hardened layer.

- Expand the R-corner of the fillet weld in the crankpin to improve the torsion strength.

- Prevents fretting by extending the crank nose 10 mm longer.

- HKS original main stud bolt with thicker screws is used.

- Enhance the strength by changing the material of #2 and #3 journals to Chromium-molybdenum steel.

- Line boring for securing the roundness of the journal.

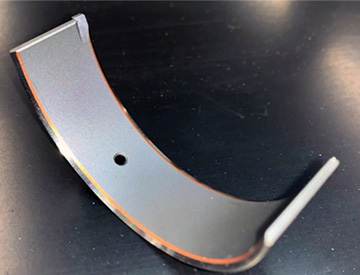

- The main bearing and connecting rod bearing are highly selected through various tests.

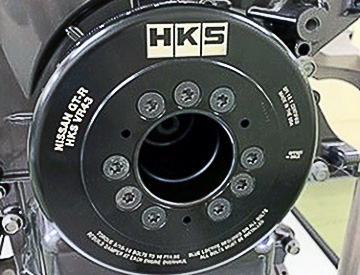

- The crank damper pulley (provided) developed only for VR43 engines reduces torsion vibrations.

-

HKS crank damper pulley only for VR4.3L

(Cooperatively developed with ATI PERFORMANCE PRODUCTS) -

Expand the R-corner of the fillet weld in the crankpin to improve the torsional rigidity of the crankshaft

-

Connecting rod bearing specially for VR4.3L

-

The billet crankshaft achieved reduced weight, improved response, and less torsion by using a high-efficient counterweight.

-

The bearing caps in #2 and #3 of the journal changed to Chromium-molybdenum steel to enhance the quality of the material. The line boring improved the accuracy of the roundness.

Specifications

| HKS 4.3L | Stock | |

|---|---|---|

| Bore | 95.5mm | 95.5mm |

| Stroke | 99.0mm | 88.4mm |

| Compression Ratio (t=0.8) | 8.6 | 9.0 |

| Allowable Rotation Speed | 7,400rpm | 7,000rpm |

| Displacement | 4,255cc | 3,799cc |

SHORT BLOCK VR38 4.3L STEP Pro

| Block Modifications |

#2, #3 Chromium-molybdenum steel made cap |

|---|---|

| Provides the Clearance for the crank contacting section |

|

| Thicker main bearing screws | |

| Enlarged bore and counter boring in the ladder beam bearing cap |

|

| Main bearing journal line boring | |

| Honing | |

| Main Bolt | HKS M12 stud bolt (625+) |

| Piston | HKS billet, Molybdenum coating |

| Connecting Rod | HKS H-beam (Clearance for fillet weld portion) |

| Crankshaft | Nitriding steel billet (Tungsten crankshaft weight) |

| Ion Plasma Nitrided | |

| Expanded R-corner of the fillet weld in the crankpin |

|

| Extending the crank nose for attaching crank damper pulley. |

|

| Main Bearing | Made by ACL |

| Connecting Rod Bearing |

Factory, fine particle peening (WPC treatment) |

| Crank Pulley | HKS product for VR43 only |