Code No. 23004-AM004

Con'rod is the weak point of 4B11 engine. Upgrading of con'rod is required for performance enhancement.

HKS developed "Forged I-Beam" connecting rod, which is "Strong" and "Affordable".

<POINT-1> "Strong and affordable" is the concept of the "Forged I-Beam" Con'rod

- I-Beam was selected for 4B11. It is strong and affordable with "high grade chromium molybdenum steel", "carburizing heat treatment" and "fracture splitting manufacturing for the big end".

- Although it looks like stock part, it is strong enough for high performance tuning vehicles.

H-Beam connecting rod

- Although it is strong against torsion, it is hard to absorb torsion.

- Lighter weight than I-Beam for the same strength level.

- Shaving process is more and expensive. (For high performance vehicles.)

I-Beam connecting rod

- Although it is used for mass production vehicles, even Formula 1 engines use this shape.

- Although it is weak against torsion, I-Beam absorbs it.

- It is heavier than H-Beam. Easier production.

- As explained above, H-Beam and I-Beam have their own merits and demerits.

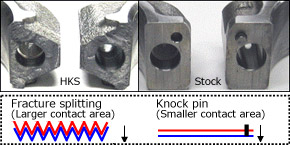

<POINT-2> Fracture splitting manufacturing method, which has high connection rigidity, for the big end

- Fracture splitting has higher connection rigidity than normal knock pin type as the contact surfaces are more since they are uneven.

- Although the looking is not good, since they are connected with uneven surfaces, it has great rigidity as shown in the pictures below.

Although the split sections of HKS product do not look good, the unevenness enlarges the contact surface and enhances rigidity.

Knock pins are not required. Stock part with flat surfaces is not as rigid as HKS item.

Fracture splitting manufacturing method

The technology was developed in Germany. This method is widely used for variety of modern vehicles from normal motorcycles/cars to racing engines.

<POINT-3> Strength for more than 500ps

- Tested on an engine bench with GT3240 Full Turbine Kit without any problem.

- HKS Forged Piston (21003-AM003) is recommended.

<POINT-4> MADE IN JAPAN

SPEC. comparison

| Comparison | HKS I-BEAM | Mitsubishi Stock (I-BEAM) | |

| Small end size | φ23 / width 20mm | ← same | |

| Bush | Cupper billet | - | |

| Big end size | φ55 / width 22mm | ← same | |

| Center distance | 143.75 mm | ← same | |

| Forged material | SCM | SC | |

| Heat treatment | Carburizing heat treatment | Heat treatment | |

| Surface treatment | Shot peening | - | |

| Big end separation method | Fracture splitting/ without knock pin | Mechining flat surface after separate forging / with knock pin |

|

| Bolt | Material /size | SCM / M8 X P1.0 | ← same |

| Strength | 185,000 psi (130kgf/mm2) | ← same | |

| Tightening | 20Nm+ 90 deg./ limitation specified for reuse |

← same | |

| Bolt lubrication | Engine oil | ← same | |

|

Larger big end and small end enhances strength. |

[ CLOSE ]