ENGINE BLOCK COMPONENTS

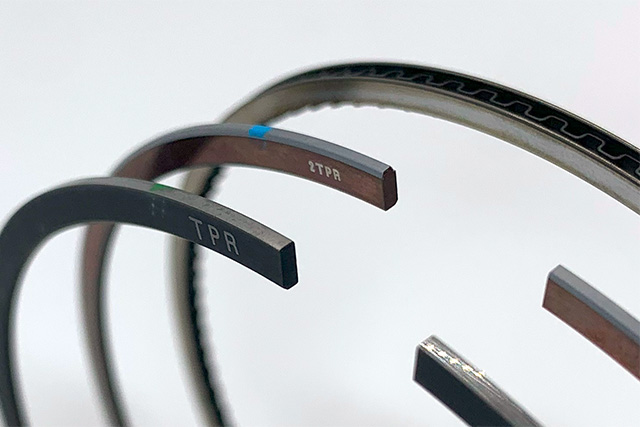

【PISTON RING SET “TYPE-LF”】

HKS piston rings are now renewed with the latest technology.

It is designed with the most advanced theory to maximize performance even under the extreme conditions.

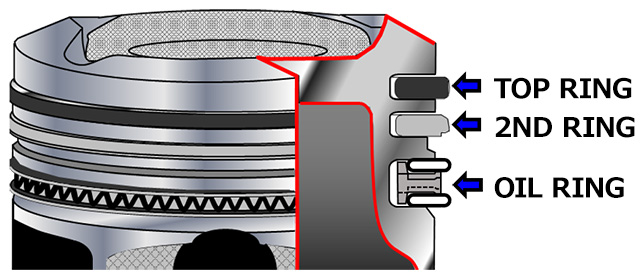

Piston rings are very important parts that determine engine performance.

The environment surrounding internal combustion engines is changing significantly, and the technology and theory behind piston rings have been constantly evolving. Now, HKS piston rings are also renewed to specifications incorporating the latest technology.

*It is scheduled to be renewed sequentially for other sizes such as D87 and D94 as well.

Features: TOP RING

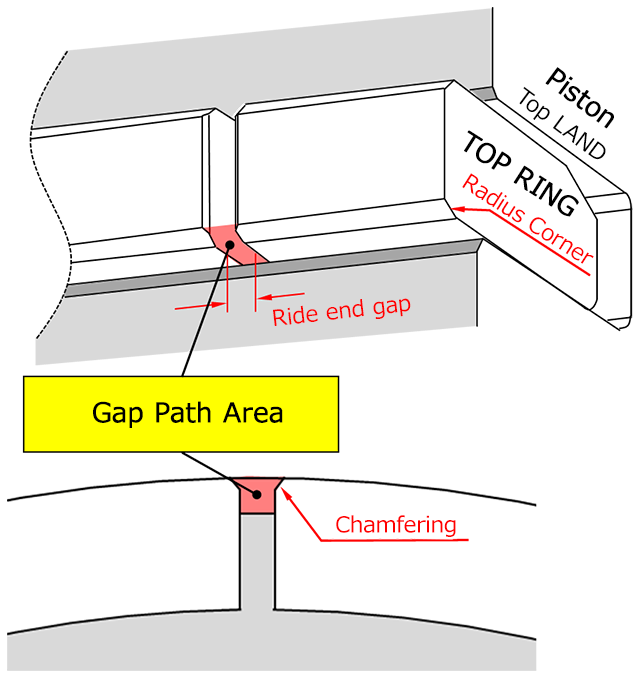

- Reduced blow-by gas at both regular and high temperatures

- The gas passage area at the joint at room temperature has been reduced by approximately 27% compared to existing products, resulting in a significant reduction in blow-by gas emissions.

- The use of materials with a high thermal expansion coefficient reduces the gap between joints by approximately 88% even during operation (at high temperatures).

- In addition, we have already confirmed the risk associated with the reduced path area, so you can use the high performance with peace of mind.

- High performance and high durability by reviewing materials and surface treatment

- The material has a thermal conductivity about 37% higher than that of conventional products. This improves piston cooling performance and reduces ring groove wear.

- Ring tension is lowered to reduce friction.

- The surface treatment has been changed to a specification that emphasizes initial blending. The thickness of the film has been changed for durability to achieve a longer life than conventional products.

Features: 2ND RING

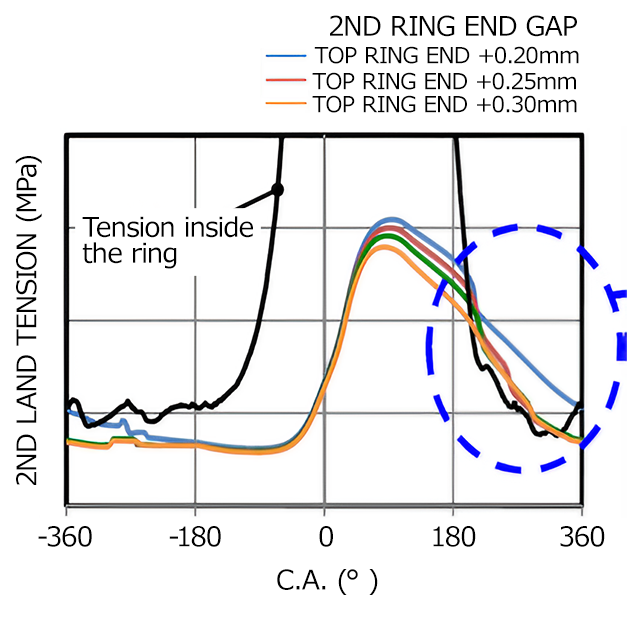

- Stabilizes the posture of the top ring and contributes to improved sealing power force.

- Gap at mating end has been enlarged by approximately 25% to reduce second land pressure.

(Even though the gap is enlarged, the sealing performance of the TOP ring has been significantly improved, so the performance is not deteriorated.) - By reducing the second land pressure, “fluttering” of the TOP ring (the phenomenon of the ring going out of control in the groove) is suppressed and sealing power is improved.

- Gap at mating end has been enlarged by approximately 25% to reduce second land pressure.

- Friction reduction

- Ring tension is reduced by approximately 18% from the conventional product to reduce friction.

Features: OIL RING

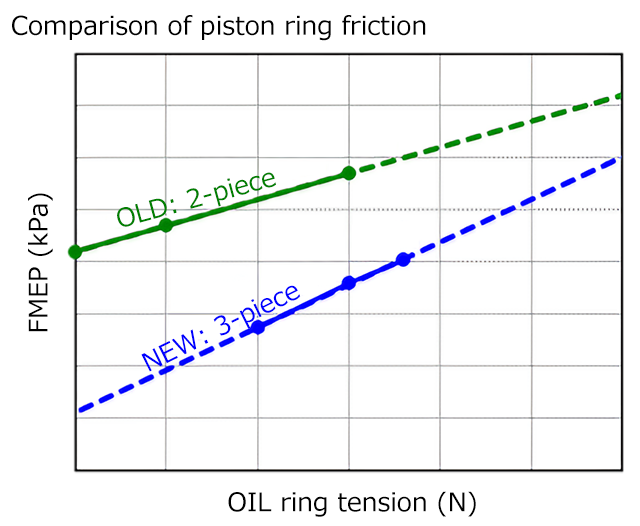

- Reduced friction achieved by 3-piece design

- We applied a 3-piece oil ring instead of the conventional 2-piece oil ring. Furthermore, by reducing ring tension by approximately 10%, friction has been greatly reduced.

- Even if the tension is reduced, the structure does not increase oil consumption. Therefore, the function of scratching oil is not deteriorated.

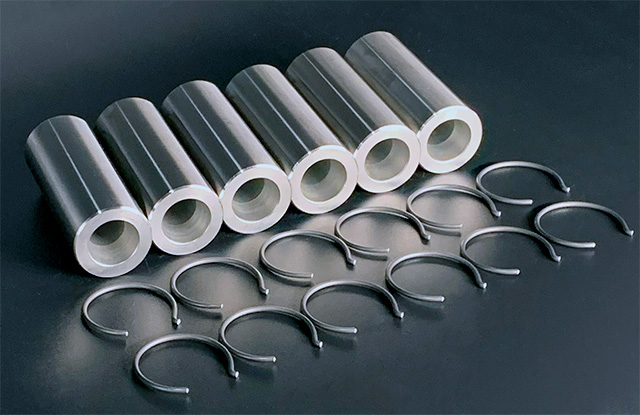

【PISTON PIN】

Piston ring sets and piston pin sets for use during engine overhauls and similar procedures have been made available as service replacement parts.

Specifications vary by lineup, so please refer to the compatibility list.