HIPERMAX SERIES

HKS Single Tube Type Suspension Leads the Way in High Performance Suspension.

"Single Tube" The key Mechanism for all HKS Suspension.

"Single Tube" The key Mechanism for all HKS Suspension.

Hipermax suspension series provide optimal dampening force, quick response to even the smallest impacts, ride comfort through a variety of conditions with a reliable stability that only inverted type dampers can provide. Drivers will be satisfied with the superior performance of Hipermax single tube suspension compared to the twin tube type that many other companies utilize.

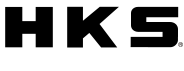

Advantages of HKS Single Tube Tech

HKS Single Tube Hyper Mechanism

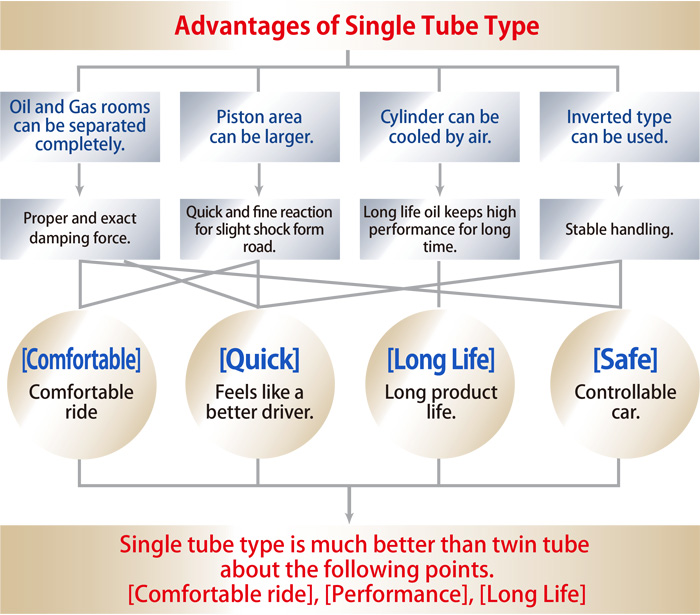

Mechanism 1: Single Tube vs Twin Tube

A single tube damper has a simple structure where a single cylindrical tube is separated into an oil chamber and gas chamber. A dampening force is generated through the movement of the piston inside the cylinder (stroke). High pressure gas to apply a constant load to maintain dampening force. Single tube has many features which allow high rigidity and durability, stability under hard driving whilst maintaining ride comfort. However, this requires a high level of design and manufacturing skill as well as the necessity to select the highest quality materials. Twin tube dampers have concentric tubes to form a two-layer oil chamber and oil flows between the two layers. Compared with single tube type, oil volume and the area in which the pressure is applied is reduced making accurate control of dampening force difficult. The twin layer design also retains heat which can lead inconsistent dampening and accelerated oil degradation. Many manufacturers choose a twin tube design as production costs can be reduced.

* What is Dampening Force?

Dampening force is the force which restricts the vertical motion of the car body. The strength of this force and the timing in which it is applied defines the performance of the damper.

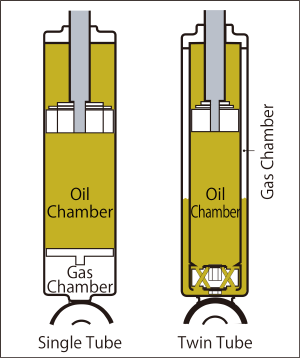

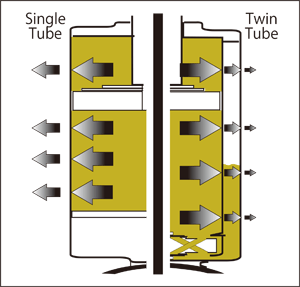

Mechanism 2: Aeration & Cavitation

Having a physical division between the oil chamber and gas chamber can massively reduce aeration and cavitation which can often occur in twin tube setups. This allows for more accurate and consistent dampening force control. This consistency and stability can deliver ride comfort which cannot be experienced with twin tube setups.

* AERATION:

The Phenomenon where gas mixes with oil or the noise which occurs when air comes in contact with the valve.

* CAVITATION:

The phenomenon where the gas contained in oil expands due to rapid pressure drop and forms large gas bubbles in the oil. Cavitation prevents proper dampening control.

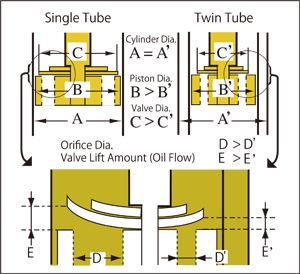

Mechanism 3: Piston Size, Valve, Orifice

Compared to twin tube type dampers, the piston area can be made larger(※). The larger diameter piston combined with optimal orifice size allows delicate response to even the smallest bumps in the road. The fine control that a twin tube design cannot handle is overcome by single tube dampers and their ability to deliver ride comfort as well as nimble handling.

*It is not a simple case of just making the piston area as large as possible. In order for the damper to function correctly, it is important to make sure that each and every part is doing its job for optimal performance and sizing is carefully calculated.

Mechanism 4: Radiation

Unlike the twin tube type, the main cylinder is in direct contact with the outside air which aids heat dissipation, whilst the increased oil volume also helps to reduce oil quality degradation. The longevity of the single tube design allows users to feel the benefits of single tube dampers for extended periods of time.

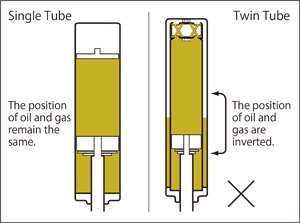

Mechanism 5: Inverted Type

By using an inverted design, which is impossible on twin tube dampers, structural rigidity is greatly improved. Greater handling and adaptation to road surface changes are all improved leading to better stability and controllability. Inverting a twin tube damper would allow gas to enter the inner tube which would cause improper operation and possible damage.

* Inverted Type and Standard Type

With inverted type, the piston rod is located on the lower side, and the cylinder is on the upper side. On strut type suspension, an inverted design can offer improved rigidity and therefore driving performance.