TUNING

5 main elements of the engine tuning

Intake Parts

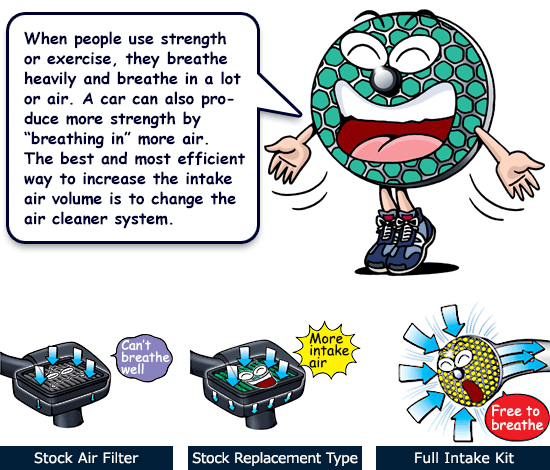

In order to increase intake efficiency, the most important thing is to remove anything that could become a restriction and guide air smoothly into the engine. However, the stock air cleaner is designed to reduce intake noise and to prevent the filter from being blocked over a long period of use under a variety of conditions. This makes the stock air intake system very inefficient from a performance point of view. It is like someone running a marathon wearing a gas mask!

HKS have designed and created Super Hybrid Filter and Super Power Flow as part of its intake line-up. Super Hybrid Filter is a stock replacement type filter which uses the stock air cleaner box and replaces the filter for one which allows greater air flow thus increasing overall intake efficiency. A Super Power Flow kit removes the air cleaner box and replaces it with an open filter type assembly which is able to cope with the demands of higher levels of tuning. Although these air box replacement type intake systems are able to offer increased air intake efficiency, the maintenance cycle is shorter than that of a stock air filter and so regular maintenance is a required to maintain optimum performance.

Exhaust Parts

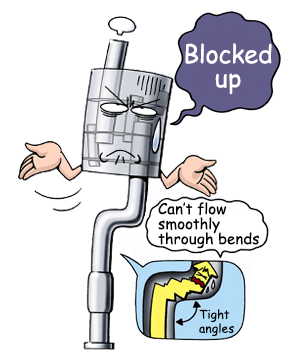

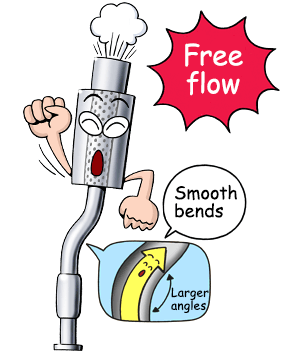

The basics of exhaust tuning are in the increase of exhaust efficiency but it is not right to assume that the least resistance leads to the highest efficiency. By removing the muffler, exhaust resistance is radically reduced but engine torque is also reduces, adversely affecting launch and vehicle acceleration so it is necessary to have just the right amount of exhaust back pressure (resistance). Exhaust manifolds are a good example of this where it is possible to change the characteristics of the engine with the shape, joins and lengths of the manifold. The exhaust system plays a vital role in the exhaust emissions and sound levels of the car. Stock mufflers tend to have tight bends and crushed areas in order to reduce production cost and layout reasons. The emphasis on the design is to reduce sound levels and gain torque at the lowest engine speeds. Sports mufflers have smoother bends to increase the efficiency of the exhaust system and each system is tuned to the specific car so that sports cars can have efficient power all through the rev range, whilst sedan and wagon cars will have more emphasis on producing torque. Sound is also tuned to suit the application whilst giving enough to state its presence. Turbos (more details later) use exhaust energy to produce power and so become a resistance in the exhaust system and so mufflers for turbo power cars are designed with less resistance compared to NA vehicles. Dependant on the Vehicle Type and muffler, it is possible to raise boost levels and gain big power increases.

Stock Muffler

Usually, the bend angle of the stock exhaust systems' pipes are rather sharp because costs, noise reduction and low speed torque are focused on when design the system. The silencer is a bulkhead structure that diffuses exhaust with a partition inside the silencer.

Sports Muffler

The sports type exhaust systems usually focus on better exhaust efficiency; therefore, the pipe bend angle is smooth, and the silencer is a straight structure that a pipe routes straight through inside the silencer. The exhaust sound level tends to become higher, but lately silent sports type exhaust systems are increasing.

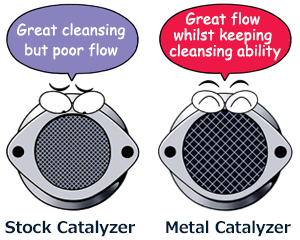

Metal Catalyzer improved both exhaust efficiency and Cleansing Properties

The catalyzer cleans the exhaust gasses so that they are less harmful to the environment. A catalyzer has a fine mesh structure with many tiny holes causing a resistance to exhaust gas flow. When considering only exhaust efficiency, best results would be achieved by the removal of the catalyzer but this would release many harmful gasses into the atmosphere and make the exhaust sound very loud. For these reasons the removal of a catalyzer from a vehicle is prohibited by law in many countries. In order to overcome this issue, the HKS 150 cell metal catalyzer was developed which has a much coarser mesh (cell) design allowing more efficient exhaust gas flow whilst maintaining cleansing properties through innovative design combining performance with social responsibilities.

Forced Induction

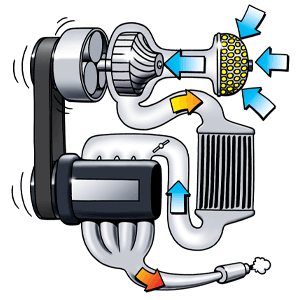

What is a Turbocharger?

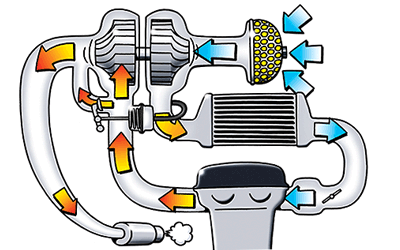

Using the energy from the engine exhaust gasses, blades like those found in a windmill are turned with a compressor which attached on the same axis. This compresses air and forces it into the engine allowing for higher outputs to be gained from the engine. The amount of air (pressure) forced into the engine is referred to as boost pressure and this can be adjusted by controlling the amount of exhaust gas which passes through the turbo. This adjustment is performed by the use of a bypass valve which is between the engine and turbo and can release the exhaust gas without flowing through the turbo. This is activated by the compressor pressure.

By raising boost pressure the engine is able to take in more air but due to limitations in engine strength and extreme combustion (known as detonation or knocking) boost pressure is limited. Stock boost pressure is normally restricted with a large margin of safety to cope with a wide variety of uses and also for environmental reasons.

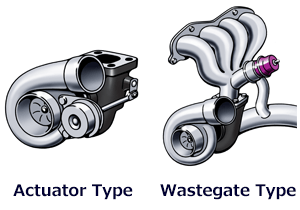

2 Types of Bypass valve

Bypass valves fall into 2 main types. Actuator types and wastegate types. Both work by opening a bypass valve when the designated boost level is reached and allowing the exhaust gas to escape without flowing through the turbo which prevents boost from rising further. They both perform the same job but the actuator is compact and can be made as one with the turbo unit, whilst the wastegate requires piping and fitting before the turbo, bypass capacity can be made larger on a wastegate type giving more stable boost settings. From these characteristics, it is common that actuators are used on stock and smaller turbos whilst wastegates are used on larger turbos for higher power applications.

What is "Boost Up"?

By increasing the amount of forced air into the engine, the explosive force is increased thus increasing engine output. "Boost up" increases the conservative stock boost levels to release the full potential of the stock setup. The most common way to raise boost is to fit an EVC (Electronic Valve Controller) boost controller. It is also possible to replace the actuator for one with a stronger spring. Although Boost up is a relatively simple way of increasing power, there are many possible complications such as knocking fuel control or boost cut that could lead to possible engine damage and so it is important to be aware of the vehicles capabilities.

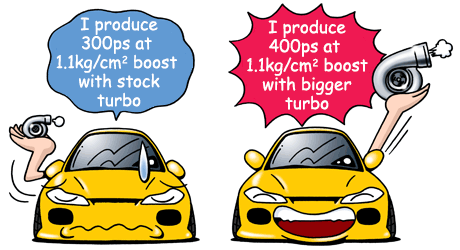

What is "Turbo Swapping"?

Turbo swapping is the next step up from boost up. The limitations of the stock turbo can be easily reached and for those who require more can replace their turbo for one which can handle more air flow.

Normally, one would think that with the same engine and boost pressure, a small turbo and large turbo would both produce the same amount of power. However this is not the case and the larger turbo will produce more power. This is caused by the difference in turbo efficiency as each size turbo has a boost pressure (air flow rate) that it can work most efficiently at and using inefficient boost pressure will cause a rise in air temperature reducing air density thus reducing the amount of air into the engine even at the same boost pressure.

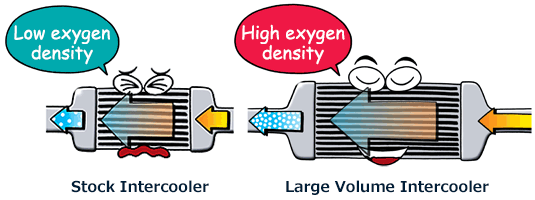

What is an Intercooler?

An Intercooler is a heat exchanger (cooling device) which is designed to cool air which has been heated by the turbo during compression.

Popular tuning in this field involves the addition or replacement of the intercooler for one of higher capacity and efficiency. A good intercooler must be able to reduce the resistance to air flow (pressure loss) and also reduce the air temperature as much as possible. These are two opposite properties and so it is difficult to achieve both together. HKS have continued to develop intercoolers in the pursuit of achieving both criteria.

What is a supercharger?

As opposed to a Turbocharger which uses exhaust gas power, a supercharger borrows a little power directly from the engine to operate a compressor. Specifically, it is most common to use a belt and pulley from the engine crankshaft to turn the compressor. As a result, the compressor will work from low rpm giving good response from the moment the accelerator is depressed. With a turbo which uses exhaust gas flow there is a delay before the exhaust gas flow necessary to operate the compressor is generated. However, at higher engine speeds (rpm), superchargers which use engine power, tends to becomes less efficient than a turbocharger.

Common Supercharger types

Roots Type: 2 rotors mesh together and push air out of a housing. Most conventional superchargers are of this type. Since a roots type supercharger does not compress air inside within the unit, a larger housing can be required for big power outputs.

Centrifugal Type: Shaped like a turbo but is driven directly by the engine rather than by exhaust gas. The internal structure divides into several further subgroups. HKS uses what is referred to as "Torque Reaction Drive Type" and with internal compression and traction drive mechanism, is able to provide suitable compression at all engine speeds.

Go To HKS Product

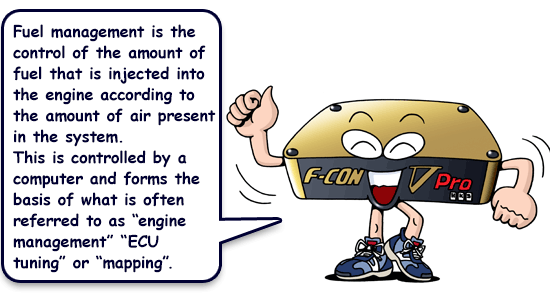

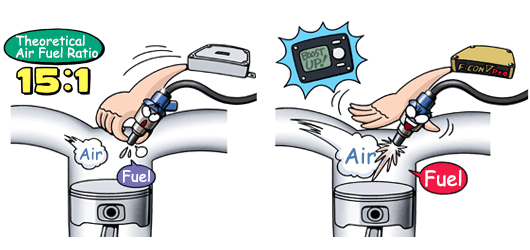

Fuel Management

In order to burn fuel completely, it is necessary to have approximately 15g of air for every 1g of fuel (15:1) and this is called stoichiometric air fuel ratio. However, in practice an engines air fuel ratio tends to be richer in fuel than the stiochiometric ratio due to conditions like the atomisation of fuel (how well the fuel mixes with air) and the cooling effect that the fuel has on the engine. An A/F (air fuel) gauge is used to measure the ratio and many stock control systems will use an O2 sensor to make rough adjustments. Under normal conditions, the cars on board computer measures the amount of air that the engine has drawn in using an air flow meter, and calculates the necessary amount of fuel needed. This relies on the vehicle being under standard conditions and once the amount of air is altered through "boost up" or similar, then fuelling should generally be adjusted to suit. When setting the fuelling, it is possible to draw on experience but the use of an A/F gauge and a data logger, which can record various different parameters, is common practice.

HKS has developed F-CON as a product which can control fuelling. Alterations are made to the injector signal to control the volume of fuel under various circumstances. It is also possible to alter the air flow meter signal to make the stock computer detect a different air flow to what is actually present to affect the fuelling. HKS AFR and FCD are products of this type.

F-CON V Prois complatible with D-Jetronic systems

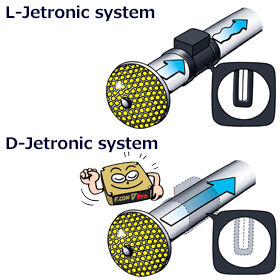

In many conventional setups, the amount of fuel to be injected is calculated though an air flow meter using what is often referred to as an L-Jetronic system. L-Jetronic systems typically use a hotwire sprung sensor which is placed in the intake piping which can restrict air flow and also has limitations to the volume of air they can measure. D-Jetronic systems use a pressure sensor inside the intake manifold to measure the amount of air present and so it becomes more efficient for air flow. D-Jetronic systems can also be known as "airflow-less" and using F-CON V Pro can turn an L-Jetronic system into a D-Jetronic one.

Fuel adjustment tool to promote complete combustion

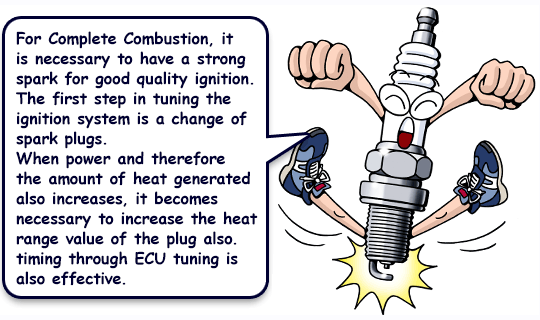

Ignision

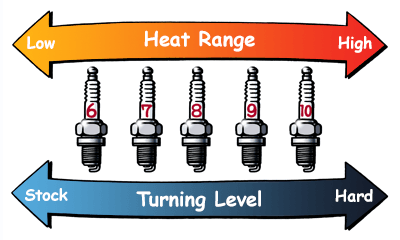

The most popular option when tuning the ignition system is a change of spark plugs. Spark plugs have a heat range value and generally lower values (low heat range type) are appropriate for use in lower heat conditions, however in hotter conditions, the spark plugs can cause knocking (detonation). High heat range spark plugs work well at higher temperatures but can cause weaker ignition at lower temperatures and possibly misfire. During boost up or other tuning, the explosive force within the combustion chamber is increased raising the temperature which makes it easier for knocking to occur which could lead to engine damage and so it is necessary to change to higher heat range spark plugs.

It is also important to control the timing of the ignition which is usually achieved through computer control like the fuelling. Ignition timing denotes when the fuel air mixture is combusted and the correct timing of this can vary depending on conditions. It is generally the case that earlier (advanced) ignition increases output but becomes more susceptible to knocking whereas delayed (retarded) ignition reduced the chances of knocking but also tends to reduce power and response. HKS F-CON products are able to fine tune ignition timing depending on the users needs.

Ignition system parts that enable strong sparks and reliable ignition