【HIPERMAX S】

Features

1. Refined from the very first movement. HKS’ proprietary tuning that softens initial input.

By reducing the harshness often felt over small road imperfections, the difference is immediately noticeable the moment you start driving. Designed to deliver an unprecedented level of ride comfort and quality—even in everyday street driving.

2. Street-level comfort and driving enjoyment, perfectly balanced. Supple suspension movement created by our FLAT RIDE CONCEPT.

With the FLAT RIDE CONCEPT (FRC), low-speed driving comfort is preserved while vehicle attitude changes during cornering are controlled in a smooth and natural manner. This results in a carefully tuned balance—comfortable on the street, yet confidently and enjoyably responsive through corners.

3. From city streets to winding roads—and even spirited driving. Wide-range optimization enabled by the WR Needle.

A defining feature of the HIPERMAX S, the WR Needle provides an exceptionally wide damping adjustment range, allowing precise tuning to suit different driving conditions and personal preferences. From everyday street use to sporty driving, a single setup delivers true versatility—engineered to adapt to a wide range of driving styles.

Advanced tuning for the next evolution of Driving Comfort

Backed by three consecutive All Japan Dirt Trial Series titles and more than 50 years of motorsports involvement, HKS applies proven, competition-derived expertise directly to the development of its suspension systems.

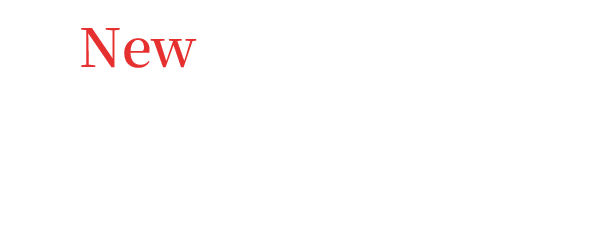

1. Aluminum Upper Mounts

The aluminum upper mounts feature a carefully selected shot-blasted finish. Extensive prototyping was carried out to achieve a refined, matte texture that delivers a calm and premium appearance. To provide a more controlled feel than the factory upper mounts, reinforced rubber is used to strike the ideal balance between firmness and compliance. This helps absorb fine body vibrations, contributing to smooth, supple driving comfort. Depending on vehicle characteristics, both pillow-ball upper mounts and reinforced rubber mount options are available.

2. Dedicated Springs

The springs are manufactured using a high-grade material not found in standard industry specifications. Cold-formed in-house at HKS facilities, they deliver exceptional quality, consistency, and long-term durability. In addition, the spring rate is now clearly printed on each spring, providing improved identification and ease of setup.

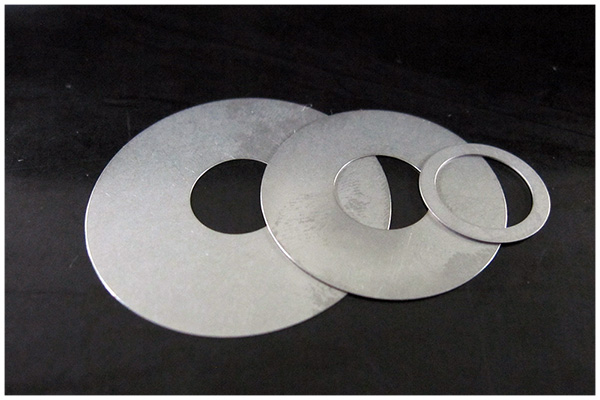

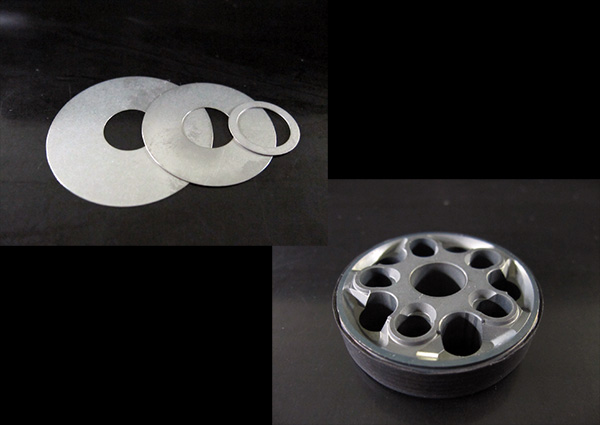

3. Valve Shims

High-quality, Japan-made valve shims are used to ensure consistent performance. A special surface treatment is applied to prevent shim adhesion, allowing smooth operation and stable behavior. This design enables precise control of oil flow under all operating conditions, delivering reliable damping performance in any environment.

4. Inverted Monotube for Strut-type Applications

For strut-type suspensions, an inverted monotube design is employed to robustly support the loads acting on the suspension. This structure enhances rigidity and stability under driving loads, contributing positively to overall performance. As a result, the suspension delivers superior handling precision while maintaining excellent driving comfort across a wide range of driving conditions.

5. Spring Insulator

As a suspension spring compresses and extends, it is constantly subjected to rotational forces. If resistance is present, the spring cannot perform as intended. By incorporating a spring insulator, these rotational forces are relieved, allowing the spring to move freely and ensuring smooth, consistent compression and rebound.

6. PNE Coating

The PNE coating prevents thread seizure caused by corrosion—one of the common issues with full-length adjustable suspension systems. Its smooth surface finish also reduces friction, requiring less force when adjusting ride height.

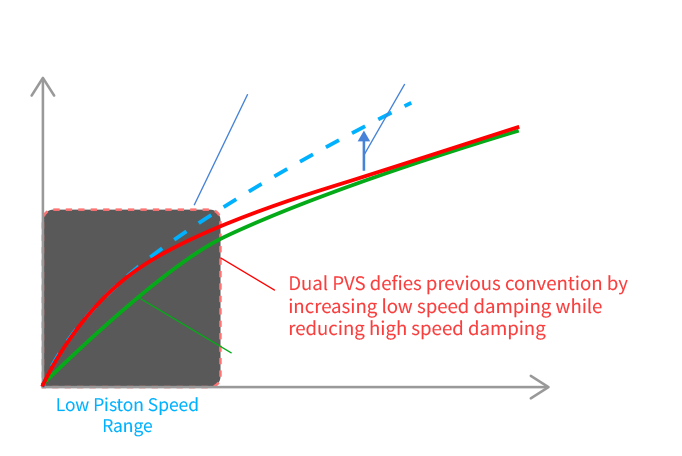

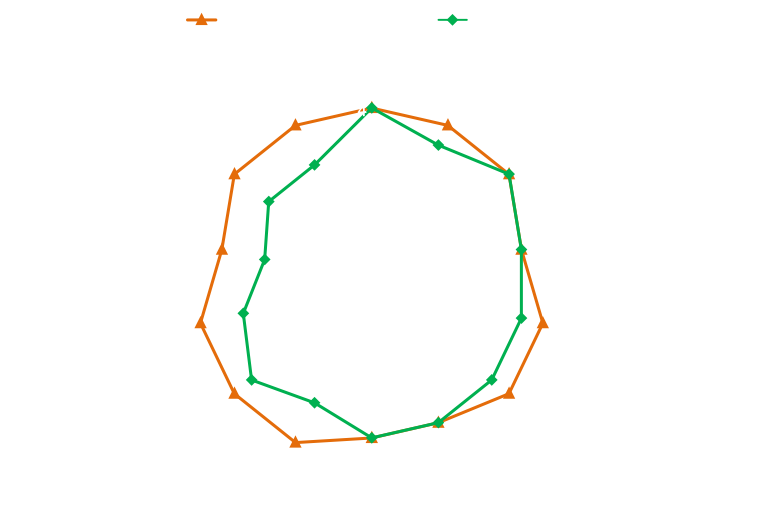

Dual PVS: Dual Preload Valve System

The rebound characteristics are refined for smoother response while suppressing unnecessary movement. To realize the further-evolved FLAT RIDE CONCEPT of the new-generation HIPERMAX S, the system is optimized individually for each vehicle application. By optimizing damping force characteristics, a new dimension of driving comfort is achieved.

Dual PVS Damping Force Curve

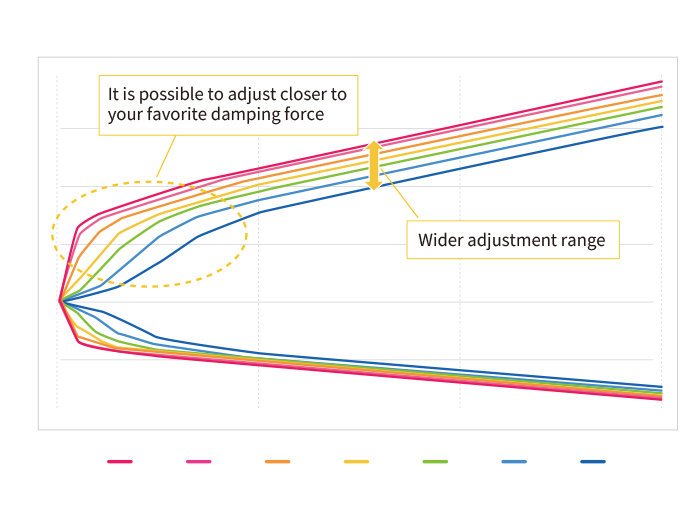

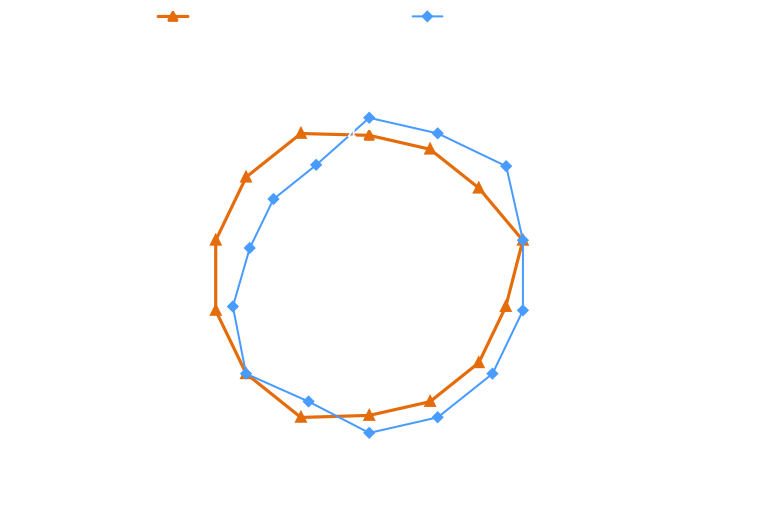

WRNeedle: Wide-Range Damping Adjustment Mechanism

The shape of the damping adjustment needle has been redesigned to vary oil flow more effectively, incorporating an increased relief passage and a needle profile with a wider range of adjustment. By expanding the adjustment range toward the softer side, greater flexibility in soft-setting tuning is achieved. From a wide selection of needles with different characteristics, the optimal specification is selected for each vehicle. This enables highly adaptable suspension settings that perform consistently across a broad range of driving situations.

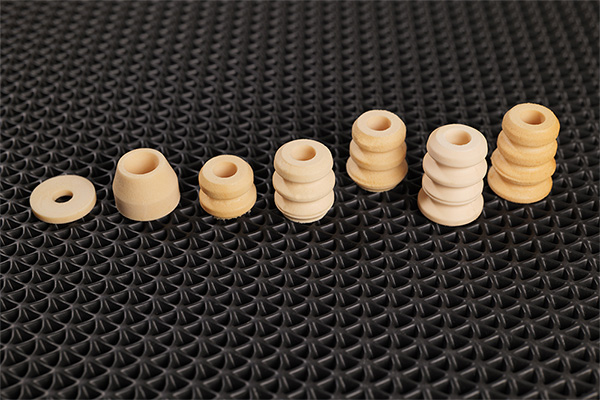

Advanced Bump Rubber Plus

The design retains its characteristic of engaging bump contact early in the suspension stroke, gradually increasing load in a controlled manner. With an expanded range of shapes now available, the optimal specification is selected from a broad lineup to match each vehicle application.

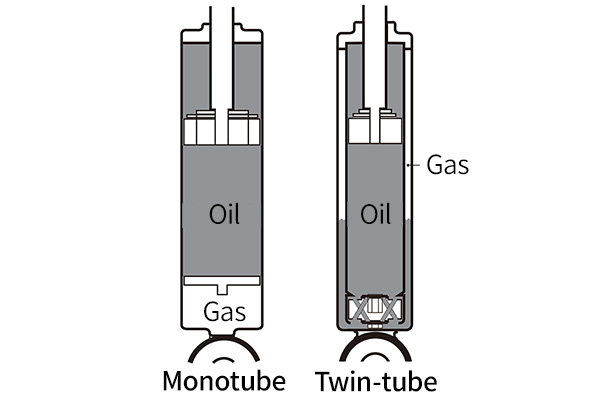

Monotube Damper Design

Continuing the HIPERMAX series tradition, a monotube damper design is employed. This structure separates the gas chamber from the oil chamber and allows the use of a large-diameter piston, resulting in refined and highly stable damping force characteristics.

3-Year / 60,000 km Warranty & Rebuildable Design

Built to a high-durability specification, the system is backed by a 3-year or 60,000 km warranty and is fully rebuildable. By expanding in-house development capabilities and introducing dedicated durability testing equipment, HKS is now able to conduct quantitative evaluations and establish strong correlation between bench testing and real-world vehicle testing. After successfully passing rigorous bench durability tests, the suspension has also completed over 60,000 km of real-world driving validation, providing clear internal evidence of enhanced durability. HKS takes pride in its fully integrated in-house production system, where strict quality control is ensured at every stage—one of the greatest advantages of complete in-house manufacturing.

Dust Boots and Stabilizer Links Now Covered Under Warranty

DURA BOOTS

The dust boots have been developed from the ground up with a carefully selected new material offering outstanding heat resistance, weather resistance, and ozone resistance. This significant improvement in durability over conventional designs makes the 3-year / 60,000 km warranty possible.*1

Designed to protect the suspension even under harsh operating conditions, these are truly tough dust boots engineered for long-term reliability.

NEW Stabilizer Links

Designed to achieve geometry optimized specifically for HIPERMAX S, the new stabilizer links feature ball joints that significantly reduce friction at the joint interface. This allows the suspension to move freely and smoothly, minimizing resistance and enhancing overall suspension response. The durability of the boot section is equivalent to that of OE components, making the 3-year / 60,000 km warranty possible.

Radar chart

Comparison with up to 2025 models (example)

Series Comparison (Image)

movie

Comparison chart

Choose- Choose your best HIPERMAX-

HKS suspension generates optimum damping force, delivers optimum traction in any driving situation and responds linearly to any road conditions to achieve both ride comfort and driving performance.

-

For those who want to focus on sports driving performance on the race track, but do not want to sacrifice driving comfort in everyday use

-

For those who desire a higher grade of "driving comfort" that is enjoyable and comfortable on any stage

-

For those who wish to enjoy an overwhelming sense of quality that is different from the stock, but comfortable like them.